Designed to meet today’s requirements for good protection of hydraulic components on machine tools, industrial equipment, construction machinery, farm equipment, or wherever close tolerance parts would be damaged by contaminated oil.

A large flow-area bypass valve, built into the head of the filter, cracks at 35 PSI (2.45 BAR), preventing damage to element if flow is restricted due to contamination. Mounting filter at pump discharge port protects all valves, cylinders, motors and rotary actuators.

FEATURES

- Built-in bypass valve.

- In-line type designed for 3000 PSI (207 BAR) operating pressure.

- Inexpensive.

- Low cost replacement parts.

- 40 nomial micron retention.

- 3 & 12 micron absolute.

OPTIONS

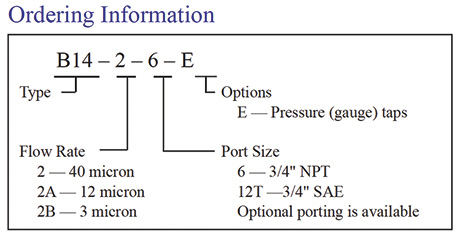

- Taps for Differential Pressure Indicator

- E.P.R. amd Viton available

- Optional porting available

SPECIFICATIONS BY MODEL

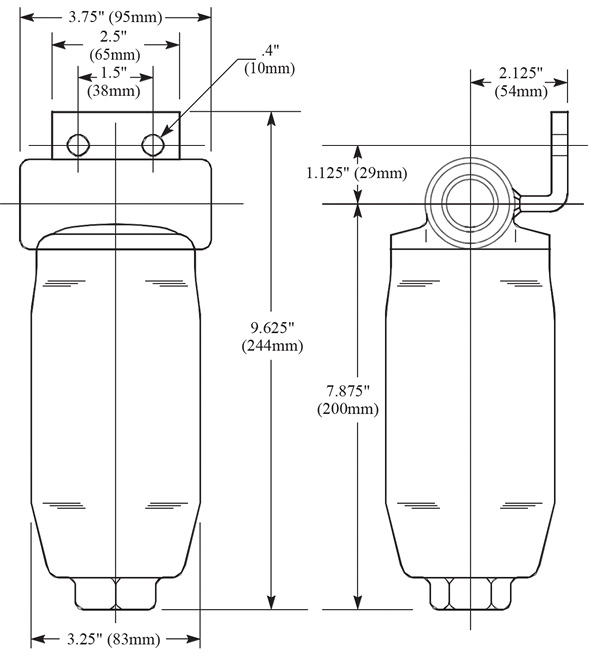

Model B 14-2:

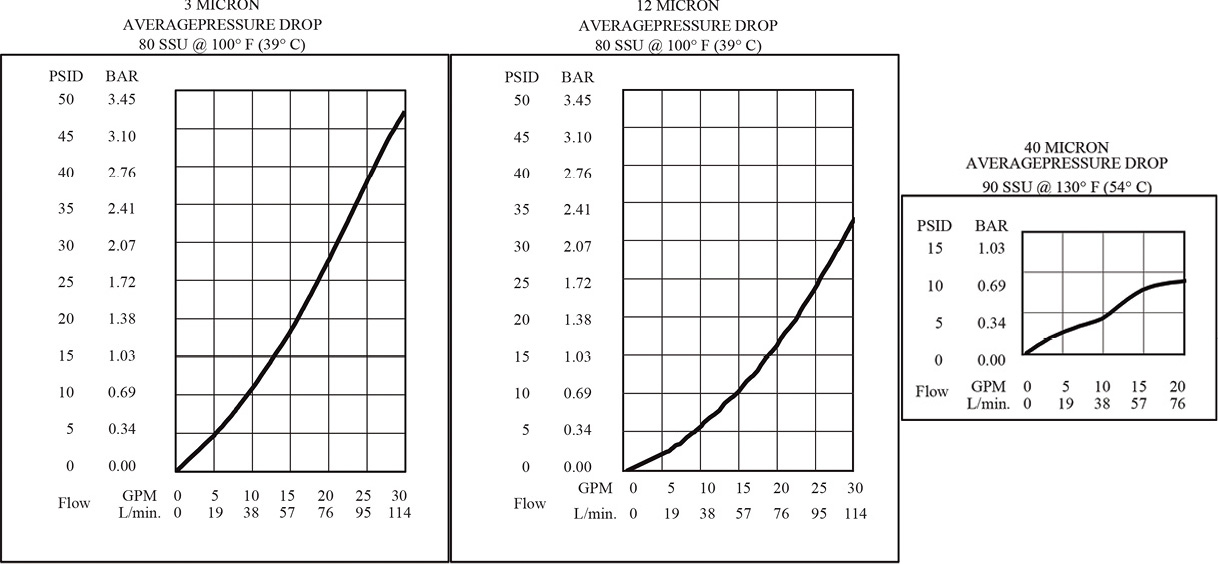

Capacity: 20 GPM (75.7 L/min.)

Filtration: 40 micron nominal 75 micron absolute B40 = 96

Element Area: 26 in.2 (167.7 cm2)

Element Type: Ribbon lamination

Model B 14-2A:

Capacity: 20 GPM (75.7 L/min.)

Filtration: 12 micron absolute 5 gram holding capacity B12 = 200

Element Area: 94 in.2 (606.5 cm2)

Element Type: Micro Glass

Model B 14-2B:

Capacity: 15 GPM (56.8 L/min.)

Filtration: 3 micron absolute 4.8 gram holding capacity B3 = 200

Element Area: 94 in.2 (606.5 cm2)

Element Type: Micro Glass

200 PSID Collapse

3000 PSID Collapse Available